A recent focus at the University of Kentucky in the Department of Mining Department has been on creating value from ‘invaluable’ products, like extracting critical minerals from coal refuse. The idea of recycling and creating value from waste has become the forefront of the program for the Mining Engineering degree. Here at UK, students and faculty alike are redefining the end of life for products in search for raw materials. Electric vehicles have become more popular, the massive amounts of raw critical minerals required to create these electronic vehicles (EVs) are causing western companies like Tesla to import these materials from developing countries. The mining program is working towards educating students to develop and create transferable skills to work in different parts of the mining industry while highlighting skills that can be used for electronics and other forms of recycling. There is an issue of governments and companies wanting to export the final product rather than the raw materials. The solution to these problems is to buy the finished product from another country, buy the raw materials to ship home or to recycle the materials from the disposed of electronics. Dr. Jack Groppo, Director of Undergraduate Studies for the Mining Engineering program. Dr. Groppo is one of the most informed and passionate people when it comes to the Mining program and its students. When speaking on EVs and electronics recycling, Dr. Groppo says, “As a general practice, here in the United States, we export most of our e-waste to developing countries that have lower labor rates, and unfortunately more lenient environmental restrictions. Places like India and southeast Asia, places like Ghana and Nigeria. They have unfortunately become dumping grounds for our e-waste.”

The mineral processing (MNG 301) course is a staple of the program, where students get hands-on experience crushing rocks and shredding electronics. Using those techniques, Dr. Groppo encourages students to develop their industry skills. To describe the course, Dr. Groppo says, “Mineral processing exploits the physical differences between the materials we are trying to recover and those we do not. That could be density, size, surface properties or conductivity; anything that is an intrinsic or an inherent property of the mineral phase itself.”

Conner Meador is a graduating senior in the mining engineering program. Like the rest of his peers, he took the minerals processing course. The course utilizes skills and principles used, like shredding and physical processing skills. When asked about the course, Conner said, “Due to the nature of the research Dr. Groppo was conducting at the time, many of the demonstrations of the processes were done using electronics scrap, and thus mining students here at the University of Kentucky have done some basic electronics recycling at least on a demonstration level.” Dr Groppo has shifted his programs around to match the growing concerns for materials recycling.

Over the pandemic, Dr. Groppo worked with his daughter, a history professor at EKU, to develop another course that falls under the Global Dynamics UK Core category. Conflict minerals: Global Demand and Sustainability (EGR/MNG 260) is a course that addresses areas where minerals are prone to armed conflict. The course focuses on asking questions like “How do we handle these issues, as privileged Americans?” Coltan from central Africa, mined artisanally by hand, is essential to make capacitors that are used in many electronic devices. There is no tantalum in the United States, but it is in a similar situation to the story of blood diamonds artisanally mined in Africa often by force. Sapphires, jade, talc, amber, sand, etc. all have similar stories globally. This class is important because it faces the issue of the hardships of mining that many students likely have not faced or heard about as well as sharing stories with different contexts to the mining experience in the United States. In addition, providing access for non-mining engineering students allows for inclusivity and experience sharing.

Aiden Adkins is a freshman mining engineering student. His interest in the program comes from having an alumni parent and being surrounded by mining and the mining industry all of his life. He recently took the conflict minerals course. “When I saw how these minerals were mined it made sense as to why we are working to recycle electronics,” Adkins said. “The minerals that are used in electronics are hard to extract from the earth, but with the recycling of electronics, it can allow for easier access to these minerals. One of the topics we discussed in the conflict minerals class was how recycling electronics can put an end to illegal mining practices.”

E-waste and creating ‘value’ from “invaluable waste”

At CAER, in partnership with the mining department, there’s been a significant focus on creating value from invaluable waste, especially electronic waste (e-waste). Recycling critical minerals from e-waste utilizes the same principles as processing extracted materials. In the case of e-waste, the laptops or phones are shredded and put into a chemical solution where the targeted material is chemically leached out and recovered as metal copper, tellurium, lithium, cobalt, and gold. Copper is recycled more often, especially in the United States because of its high concentration in existing products. Copper is found in virtually all electronic products, and we know how much it’s worth (currently $4.07 per pound).

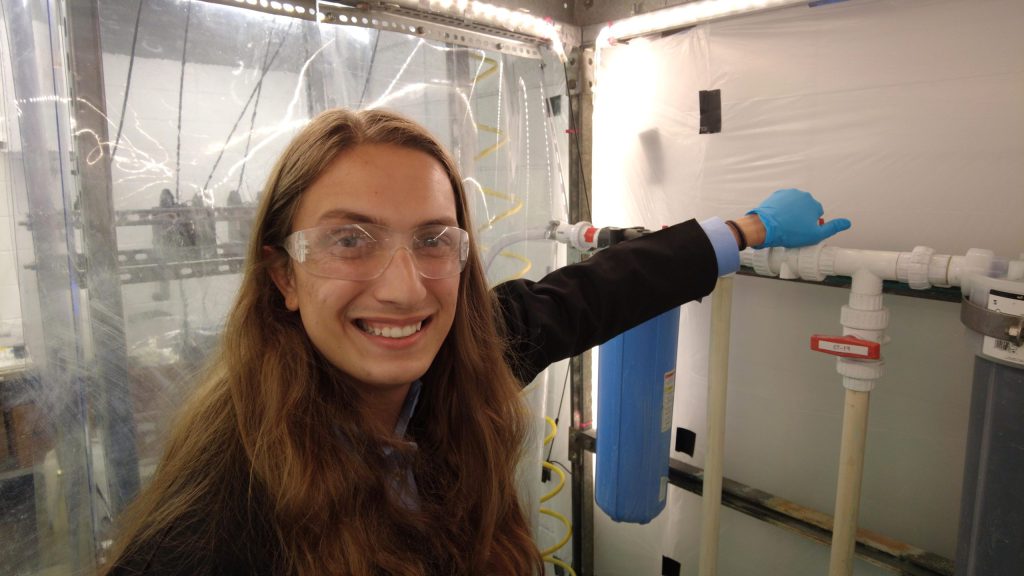

Lucas Bertucci is a graduating senior in chemical engineering. As the Lee T. Todd, Jr., Innovation Scholar, Lucas has done amazing work developing a company that focuses on recycling solar panels. As the use of solar power has become popularized, we have seen more and more issues addressing their end-of-life fate. Lucas and his cohorts have been able to break solar panels down into four major components: high-quality glass, plastic, copper product, and impure silicon metal. The glass can be recycled into other glass products. The plastic is impure and not much can be done with it. The copper is high grade (about 52% Cu). The silicon metal can be reused for other things but not in solar panels since the impurity is ingrained in the silicon.

Lucas spoke about his business, “By 2030, end-of-life solar panels will be worth a combined total of $450 million in recycling potential. While the green energy revolution is sweeping the globe, little consideration is being put into what to do with broken, old and unusable solar panels. My proposal for this program is to develop an environmentally friendly and economically sustainable process for recycling solar panels.”

Mining and mining engineering has always had an international scope. This level of competitive cooperation is unseen in many other fields, which is likely because everyone needs coal, and it is the predominant energy source. Coal was at the heart of the program for a long time, with UK being one of the best schools to go to for their mining engineering programs. Coal was the resource for funding and exploratory research. Recently there has been a shift from studying coal to other forms of energy and end-of-life products. There has also been a focus on critical minerals which are found in e-waste. The United States does not have enough minable, raw critical minerals. We must either recycle it from electronic e-waste or pay other governments for it. We need these critical minerals for the modernization of electric infrastructure. To learn more about the mining engineering program, visit: https://www.engr.uky.edu/research-faculty/departments/mining-engineering