Carbon Materials Developing innovative materials to improve strength, efficiency, and sustainability.

Improving Carbon Fiber Technology

Carbon fiber is the material of the future — a next-generation version of aluminum. Its properties are often considered the holy grail in manufacturing. Carbon fiber is a low-weight, high-strength, corrosion resistant material that can conduct electricity. The University of Kentucky Center for Applied Energy Research (UK CAER) is home to the largest carbon fiber spin line at any institution in North America. Over the past decade, our researchers have built a solution spinning line that draws visitors, collaborators, and research partners from across the Commonwealth, the nation and the world. And they are here for one thing: to lean on UK CAER’s carbon fiber research team as they seek answers to some of the toughest questions facing the industry.

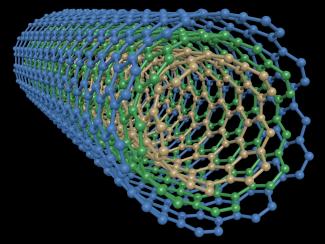

Exploring the Potential of Carbon Nanotube Technology

When carbon nanotubes (CNT) were first discovered in the early 1990s, it sparked a revolution in materials science. These incredible structures have an array of fascinating electronic, magnetic and mechanical properties. CNT are at least 100 times stronger than steel, but only one-sixth as heavy, so nanotube fibers could strengthen almost any material. Nanotubes can conduct heat and electricity far better than copper. CNT are already being used in polymers to control or enhance conductivity and are added to anti-static packaging. For nearly two decades, UK CAER scientists have been involved in multi-walled carbon nanotube (MWCNT) synthesis and research. During that time, the carbon materials group researched many of the desirable properties that MWCNTs exhibit, including strength, stiffness, electrical conductivity, and thermal conductivity. Additionally, the group has worked extensively to make multi-walled carbon nanotubes more accessible by driving down their cost through continuous production technology.

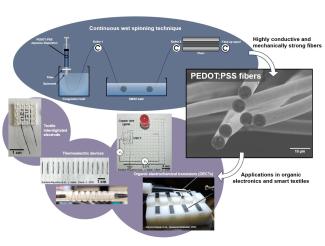

PEDOT: PSS Fibers

Poly(3,4-ethylenedioxythiophene): poly(styrenesulfonate) (PEDOT:PSS) fibers are p-type conductive polymer fibers that combine excellent electrical and mechanical performance, making them attractive for wearable and flexible electronics. Using a continuous wet spinning technique developed at UK CAER, these fibers achieve conductivities exceeding 2000 S/cm, along with a tensile modulus over 15 GPa. Ongoing work is focused on advancing multifilament spinning for production of continuous fiber tows for greater processibility. Our single filament fibers have already been applied in a range of applications, including organic electrochemical transistors (OECTs) and thermoelectric devices.

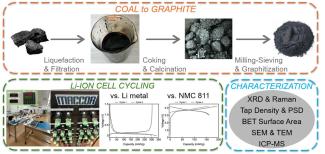

Coal to Graphite for Batteries

We convert coal – one of the most abundant and affordable carbon source – to synthetic carbon (e.g. graphite and hard carbon) to create high-value, carbon negative electrodes for energy storage. On the front end, our research focuses to increase the efficiency, and yield of the processes to make graphite. On the application side, we are focused on understanding how the microstructure of the active material – dependent on the precursor and high-temperature treatment – affects the electrochemical performance. Our dry lab is fully equipped for the fabrication and testing of both coin and pouch cells.